FRISBI

Overexpression of recombinant protein in yeast benefits from the absence of size limitation and the possibility to overproduce several factors simultaneously.

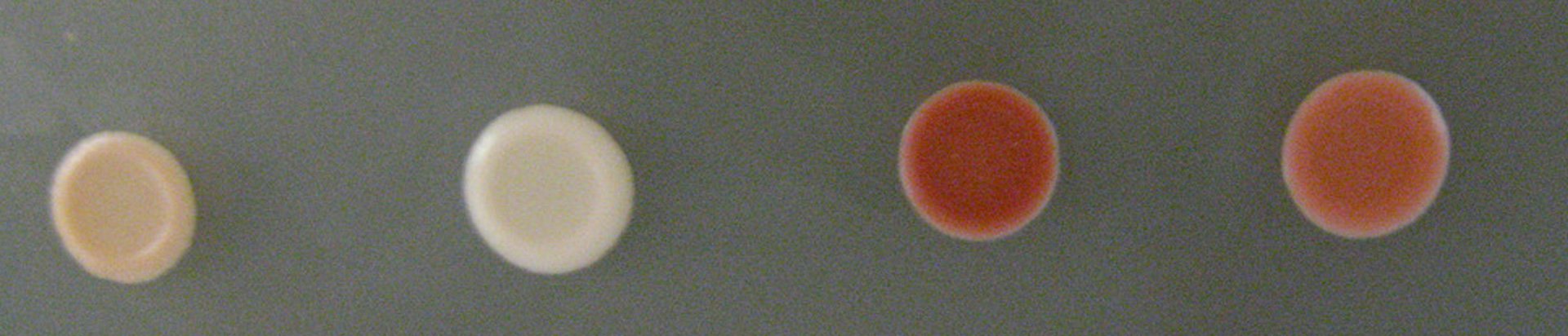

Overexpression of genes of interest in Saccharomyces cerevisiae is easy to set up provided that the coding sequence(s) is (are) fused to appropriate control regions (promoter, regulators…). While users have the choice of many parameters (e.g., regulated versus constitutive promoters, plasmidic versus chromosomal expression…), the preferred system involves overexpression driven by a galactose regulated strong promoter from a multicopy plasmid. The procedure consists then in the construction of the expression vector, chemical yeast transformation and culture under a selective medium.

Because protein yields can be lower in yeast than in a bacterial system, efficient purification strategies, such as TAP method, may be required. The TAP tag may be inserted in a plasmid driving protein overexpression or can be targeted to purify endogenous protein complexes.

The nature of the project will direct the choice of the expression system and the associated expression vectors. We use commercial systems and develop in-house vectors. Production can be done at different culture scales from tube (several mL), flasks (hundreds milliliters to several liters scale) to whole fermentors (over 100 L).

The platform will provide guidance to produce proteins using well-defined protocols as well as advice on the numerous possibilities offered by this host. Access can be provided at different steps but users would typically arrive on site with a DNA construct (plasmid or gene(s) of interest) to learn and be assisted with handling yeast strain transformation and culture protocols (duration of stay 2-3 weeks depending of the nature of the project(s)).

For more details see: https://instruct-eric.eu/platform/protein-production-strasbourg-france/